SmartAssembly for Creo

Rules Based Design Automation

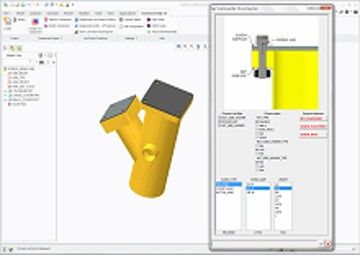

SmartAssembly is a process capture tool made for designers. A Creo users can be trained to create automation applications in a simple easy to understand language. Most applications can be written in a few paragraphs

Key Features

- Automatic creation & configuration of new parts and sub-assemblies, then automatically assembling them

- Automatic assembly of newly created or existing parts or sub-assemblies

- Creation of part level features

- Support for part family tables and assembly level family tables

- Dimensional information provided thru user input or automatically from the program

- Automatic relations from analysis features when assembling a component

- All components and features created still have full redefine or edit definition capability

- When a component is removed, the associated relations are also removed

- Rich programming flexibility – loops, conditional statements, variables, etc.

- Manufacturing and Drawing Automation Support

- Works with Pro/Intralink and PDMLink

How It Works

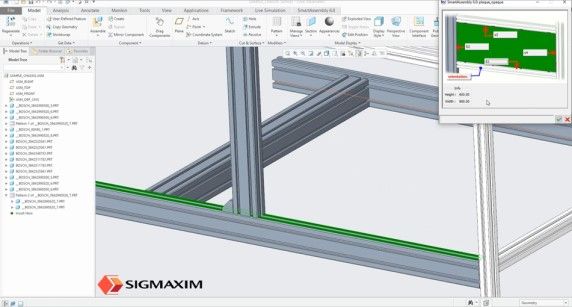

- Define required automation rules using features, standard components and assemblies, SmartAssembly programming, and the required GUI

- Work either in part mode to add features or at the assembly level to add features or components

- Define project templates and re-use the data –automatically copy, rename a top-level assembly and all drawings, parts, sub-assemblies, even manufacturing files are copied and associated to the new project

- Use the SmartAssembly GUI to speed up all design and manufacturing tasks

Key Benefits

- Standardization of assemblies and parts New users can be productive in a fraction of the time

- Productivity improvements of 50-80% are commonly recognized

- Advanced users create designs faster allowing them to focus on the design process

- Re-use company standard libraries – create automation programs from existing components in hours UDF organization – eliminates common UDF problems such as UDF naming, gph file location, or required references